Assessing the True Costs of Bin-Run Seed

Planting bin-run seed can be seen as a cost-saving measure, but it has a variety of potential downsides. The following outlines how bin-run seed can actually reduce yield and profitability compared to professionally produced seed.

Higher-quality Seed Can Increase Crop Yields

Professionally grown soybean seed consistently outperforms bin-run soybean seed, as indicated by agricultural research studies.1, 2 To illustrate this point, the following examples offer evidence of increased yield.

One study comparing the performance of professionally grown seed and bin-run seed showed that the professional seed produced greater yield than bin-run seed.3

In another study, the evidence for higher yields from professionally produced seed was demonstrated again during research trials comparing yield of soybean from professionally grown seed vs. bin-run seed. The results from experiments conducted across the country showed that professionally grown soybean seed outperforms bin-run soybean seed — up to 2.7 bushels more per acre.4

The results from experiments conducted across the country showed that professionally grown soybean seed outperforms bin-run soybean seed — up to 2.7 bushels more per acre.

According to the Seed Innovation and Protection Alliance (SIPA), plant breeding potentially enables 70% of soybean yield potential.5 With the advent of elite varieties, advanced breeding techniques have achieved an astounding annual year over year yield gain of approximately 0.5 bushels.

Bin-Run Seed Requires Additional Handling, Transportation, and Storage, which Can Add Costs

Bin-run seed is collected directly from the field after harvest. It may contain a mix of seeds from different plants and may vary in size, shape, and maturity. This can amount up to 10-15% of raw seed.6

Seed variations alone necessitate additional handling, sorting, and sizing to ensure uniform planting populations the following season. Impurities, such as different varieties, weed seeds, chaff, and other plant materials, can be found in bin-run seed. These impurities need to be removed through cleaning and sorting processes before planting to prevent interference with germination and plant growth.

Growers may consider treating bin-run seed before planting to help protect it from diseases and pests. This requires additional handling steps to treat the seed with fungicides, insecticides, and other chemicals during storage.

Cleaning, sorting, and treating may require transporting the seed to another facility. That costs additional time and money that could otherwise be spent on professionally grown seed with higher yield potential.

Leading seed companies prioritize cutting-edge seed handling technology to minimize seed damage and elevate seed quality. From planting and harvesting to storage and conditioning, seed companies treat each seed with utmost care, ensuring that it is handled as pure seed — not merely as commodity grain. In addition, leading seed companies have comprehensive systems to identify and track seed lots for qualitative analysis.

Joe McClure, Iowa Soybean Association director of research, says successful planting and early season plant health rely on seeds that were conditioned and stored optimally.

“It is important for maximum yield to have seeds that were cleaned to remove anything with damage, like seed coat cracks that can enable disease to enter or seed treatments to damage the living part of the seed,” he says.

It is equally important to maintain proper storage temperatures and moisture levels to ensure quality. Professional seed companies store seeds under ideal temperatures and humidity conditions to prevent deterioration.

“Seeds are living organisms and improper storage can lead to disease during storage and reduced germination in the spring,” McClure says.

Seeds are living organisms and improper storage can lead to disease during storage and reduced germination in the spring.

– Joe McClure, Iowa Soybean Association Director

Greg Tylka, Morrill Professor at Iowa State University and director at the Iowa Soybean Research Center, says pathogens like the soybean cyst nematode (SCN) can be spread from field to field and from farm to farm in the small pieces of soil that are present in uncleaned or poorly cleaned bin-run seed.

“SCN is very widespread in Iowa and throughout the Midwest and can move many other ways besides in clods of soil in dirty seed,” says Tylka. “But moving it with dirty bin-run seed certainly is a possibility.”

Environmental Factors Can Impact Germination

Drought and heat stress during the seed fill period tends to lower standard germination percentage on harvested soybeans. According to university research, germination percentage can be reduced 10% by severe drought, 3% by high air temperature, and 29% by the interaction of drought stress and temperature.7

Professional seed companies help to ensure seed fields are harvested at optimum moistures to prevent cracked/shattered seed. They also work with growers to plan for a timely harvest, noting wet/dry cycles prior to harvest can impact quality.

Professionally grown seed undergoes rigorous quality control measures, including germination testing during and after harvest, to ensure that it meets high standards for viability and purity. The seed is typically handled and stored in optimal conditions, ensuring its viability at planting. This can lead to more uniform plant stands, which optimize light inception, water usage, and nutrient uptake.

Professionally grown seed undergoes rigorous quality control measures, including germination testing during and after harvest, to ensure that it meets high standards for viability and purity.

More Seed Than You Think

We’ve summarized these considerations, and now it’s clear how using bin-run seed impacts the amount of seed that needs held back. This results in a higher loss of commodity grain sales than a grower likely estimates.

- Physical loss during movement of seed, transportation and the cleaning process

- Removal of non-viable seed, including splits and culls

- Higher planting rate due to likely lower germination rates to achieve the desired yield

One theory suggests that one bushel used as saved seed turns into 1.5 to 2 bushels not sold as commodity grain due to physical loss. This is somewhat conservative because more seed is required due to lower germination rates associated with bin-run seed and the removal of non-viable seed. For every bushel saved for planting is likely another bushel lost in commodity grain sales.

One theory suggests that one bushel used as saved seed turns into 1.5 to 2 bushes not sold as commodity grain due to physical loss.

Contractual Obligations

Most seed companies require growers to sign a Technology Use Agreement (TUA), especially if growers are planting proprietary seeds. A TUA is a contractual license that outlines the terms and conditions under which growers are allowed to use seed and proprietary digital platforms for crop management. In most cases, the TUA grants growers the right to plant the seed for only one growing season.

Many soybean varieties are protected by patents and or Plant Variety Protection Certificates (PVP). If you suspect a grower of potentially using bin-run seed that is protected by a patent or PVP certificate, you’re encouraged to call the Seed Innovation Protection Alliance (SIPA) Tipline: 1-844-SEED-TIP (844-733-3847). You can remain anonymous if you’re concerned about being identified by another grower.

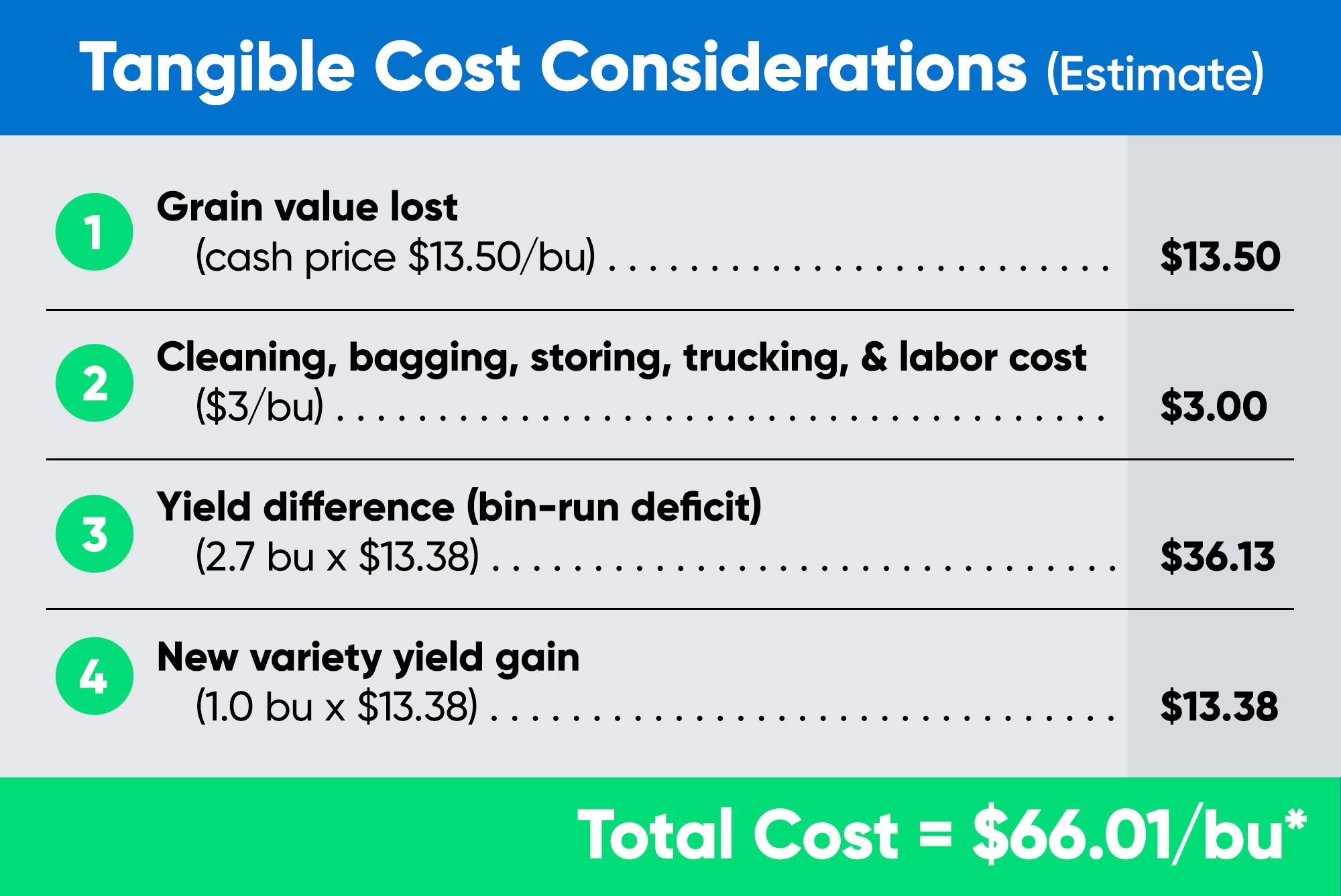

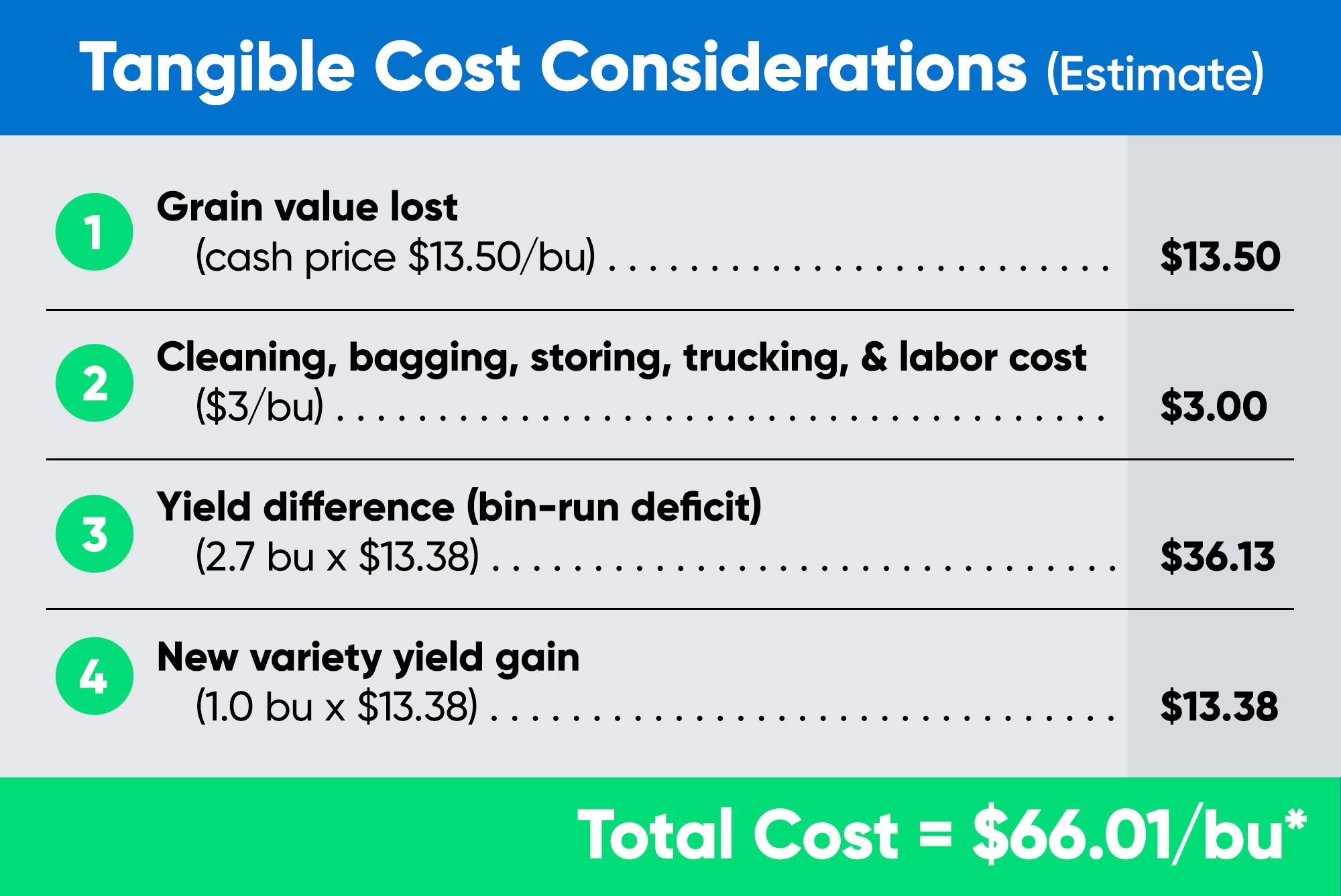

See How the Costs Add Up

Saving and planting bin-run seed can cost growers a significant amount of money each year. Check out this soybean cost considerations table8 for more information.

*Growers’ total cost may be higher because one bushel used as saved seed could turn into two bushels lost in commodity grain sales. This can be attributed to physical loss during movement of seed, non-viable seed (splits and culls), and higher planting rates.

Intangible Cost Considerations

- Authorized seed company agronomic support

- No replant support

- No returns or swapping options

- No marketing offer opportunities

1 Bin run seed – some lessons from the past. C.O.R.N. Newsletter – Agronomic Crops Network. Ohio State University Extension. April 2018.

2 Why it doesn't pay to plant bin-run soybean seed. Successful Farming, 2/12/2013.

3 Knudson, Mary and Hansen, LeRoy. 1991. Intellectual Property Rights and the Private Seed Industry. Agricultural Economic Reports 308158. United States Department of Agriculture. Economic Research Service.

4 Dunphy, E.J. and J.M. Ferguson. 1991. Field performance of farmer-saved and professionally grown soybean seed lots. Proceedings of the American Seed Trade Association Annual Meeting.

5The economic, social, and environmental value of plant breeding in the EU. HFFA Research. 3/18/2019.

6 Feedback from soybean production experts. Seed Innovation Protection Alliance, 2021.

7 Dornbos, D.L. 1988. Soybean seed yield, viability and vigor, and chemical composition resulting from drought and high temperature stress during seed fill. Retrospective Theses and Dissertations. Paper 9337. Iowa State University.

8 Bin Run vs Professional Produced Seed. Crop Focus. Pioneer DuPont. 2016.