If a weather-related event didn’t affect farming in 2023, it would be hard to name. Drought, fires, flooding, hurricanes, tornados, wind—you name it—it happened this year. Plus, it likely will go down as the hottest year on record as El Niño takes us into 2024. Knowing all of these can happen in one year gives even more reason to plan well for next year.

There’s more than weather to consider, though. To help prepare for next year, we checked with experts about weather, plant disease, hybrid and variety selection, new technology, new products, advances in equipment and risk management to examine what tools you can engage to help manage longstanding seasonal challenges and extreme weather events. Their insights will help you take the next growing season by storm.

Industy Topics

Agriculture is an ever-changing industry. From evolving challenges like herbicide and fungicide resistance to drought management to sustainability, there are many topics you may be thinking about. Get expert resources to help navigate them all and bring yourself a little peace of mind.

Other Resources

Tar Spot

Like most newcomers, tar spot, a disease that appeared in the Midwest in 2015, has drawn its fair share of attention. Rightfully so. It can rob 50 percent of a crop’s yield potential and has unfortunately progressed to being common. Under the right conditions, it causes lesions on corn leaves and reduces the leaf area, which reduces yield. Even more yield loss occurs when plants die early because of innumerable lesions overtaking the plants and plants’ health.

“We haven’t seen this kind of loss in central Iowa, but severe loss from heavily infested areas in Illinois, Indiana and Wisconsin has been reported,” Matt Vandehaar, Pioneer Field Agronomist, says. “In heavy years, some areas can have a full tar spot environment and losses can be drastic, especially if you’re growing a poorly rated hybrid and aren’t using a fungicide.”

Tar spot inoculum is present throughout the Midwest but doesn’t strike evenly. Vandehaar says it was heavy for several years in sections of Illinois, Indiana and Wisconsin, or Tar Spot Alley, as it became known. In 2022 it was prevalent in northeast Iowa and southeast Minnesota. Central Iowa had the bulk of it this past growing season.

Tar spot inoculum is present throughout the Midwest but doesn’t strike evenly. Vandehaar says it was heavy for several years in sections of Illinois, Indiana and Wisconsin, or Tar Spot Alley, as it became known. In 2022 it was prevalent in northeast Iowa and southeast Minnesota. Central Iowa had the bulk of it this past growing season.

Cool, wet, humid conditions generally allow tar spot to thrive on corn plants, but this isn’t a given. Vandehaar says central Iowa had a hot and dry summer, but high humidity and heavy dews allowed tar spot to flourish in hot spots throughout the region.

Management helps

“Two practices will lower the probability of getting tar spot,” Vandehaar says. “First, is hybrid selection. Some hybrids are susceptible to tar spot and some are tolerant to it. Second is a timely application of fungicide, depending on when the disease pressure occurs and how prevalent it is in the corn canopy.

“At Pioneer, we have listed ratings for tar spot and do our best every year to update those and our newer hybrids provide the best guidance on what those scores are. Asking for the tar spot rating for a hybrid is critical. For example, I had a plot with four Pioneer hybrids and 16 competitive hybrids. We used fungicide, and there was a 23- to 31-bushel difference between our highly rated tar spot hybrids and unrated competitive hybrids. For those areas that weren’t treated with fungicide, there was a 52-bushel difference between treated and untreated.”

Tar spot is worth considering when selecting 2024 hybrids. Vandehaar says yield is naturally the first trait followed by yield stability under stress, different soils and varying conditions.

“Tar spot and northern corn leaf blight are important hybrid considerations,” he says. “Other regions will have varying concerns. Tar spot is not the most important consideration when selecting a hybrid, but it’s a critical part.”

The possibility of tar spot infestations can be managed. “Two practices will lower the probability of getting tar spot. First, is hybrid selection. Second is a timely application of fungicide.”

White Mold

It takes seven or more years to go from a new cross to being a commercial product, and then corn is tested for two years and soybeans for one.

White mold is not the most prevalent pest in Fore’s territory, which includes parts of Minnesota and Montana, plus North Dakota. It’s a familiar one, however.

“We have white mold, but our crop rotations help keep incidences of it down,” Fore says. “Farmers in this region grow a variety of crops, including dry beans, sunflowers, sugar beets and wheat.”

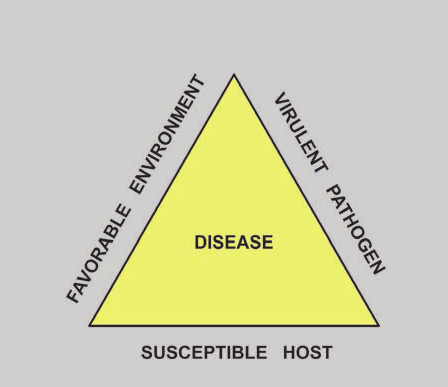

However, the rules of the disease triangle don’t change. There are times in the area when the environment, the host and the pathogen are present to create perfect conditions for a white mold infestation. Add to this white mold’s host range and managing it can be a challenge.

“White mold has a wide host range, unlike a lot of diseases,” Fore says. Many broadleaf crops are hosts for white mold, some more and some less, which makes it more challenging to manage in this region. Soybeans and dry beans are hosts. White mold can do well on sunflowers; even broadleaf weeds are hosts.

“Another unique thing about white mold is the sclerotia in the resting body or long-term survival spores, and they last in the soil and slowly degrade over five to seven years. So, if you have a host crop that produces a lot of inoculum, you must be especially careful.”

Manage to deter white mold

If you have any history of white mold in an area and you’re planning to grow soybeans next year, Fore recommends implementing management practices to control it. The first thing to do is select a variety that best fits your situation.

“We do a lot of work to develop a trait score for white mold tolerance,” he says. “Look for varieties with good white mold tolerance. There’s a good range of tolerance to it. No varieties are resistant. Also, consider plant population and row spacing. The more open the canopy is, the more things will dry out and you won’t get as much white mold. For white mold to grow, it has to be moist for hours at a time. If you dry out the canopy, the spores won’t survive.”

Secondly, a more open canopy may require wider rows and lower plant populations, lowering yield. But if a white mold infestation is severe, it can be worth it.

“There are foliar fungicides you can use,” Fore says. Viatude™ fungicide and Aproach® fungicide both contain Onmira™ for proven control, and Viatude also contains prothioconazole for two modes of action and added disease protection.

Fore adds that the timing can be tricky when planning fungicides. “In soybeans, the infection period is about a month long, and the initial spores germinate in the soil. This makes it hard to get the fungicide timing right. It’s an effective management practice and can be worthwhile in high-pressure situations. In my area, it’s generally irrigated acres. Some growers who irrigate soybeans will use all three management practices and sometimes apply fungicide twice, but their beans have yield potential, so it’s worth managing well.”

Fore acknowledges a white mold infestation doesn’t have to be forever. Sclerotia will persist in the soil for five to seven years but can eventually disseminate.

When it comes to variety selection, Fore says to review your cropping history, including varieties, environments that may be white mold inoculum hot spots, management capabilities and work with a supplier who understands selecting varieties with a balance of resistance traits.

There are times in the area when the environment, the host and the pathogen are present to create perfect conditions for a white mold infestation. “Look for varieties with good white mold tolerance. There’s a good range of tolerance to it.”

Winter Weeds

Manage winter weeds for a successful spring

With winter upon us, time for winter weed management decisions is short. Ron Joiner, Pioneer Territory Manager and Field Agronomist, says jumping on weed management decisions now, not tomorrow, will net the best ROI next spring.

“One product we’ve used extensively in the South and Southeast is LeadOff® Herbicide from Corteva,” he says. “It does a great job helping control winter annuals such as mustards and henbit. LeadOff keeps them from flowering and taking up moisture and nutrients from the soil.

“One product we’ve used extensively in the South and Southeast is LeadOff® Herbicide from Corteva,” he says. “It does a great job helping control winter annuals such as mustards and henbit. LeadOff keeps them from flowering and taking up moisture and nutrients from the soil.

“This gives us one more tool to manage moisture and nutrient availability. Plus, it keeps fields clean without additional herbicides. A nice thing about LeadOff is its low use rate – about 1.5 ounces per acre – and it is priced well. It’s very economical compared to plowing, and there’s no soil moisture loss. You’re essentially laying down a piece of black plastic to keep your fields clean.”

As Joiner says in his YouTube video demonstrating the effectiveness of LeadOff, “A picture is worth 1,000 words.”

Another economic benefit Joiner points out is that LeadOff breaks down slowly since it’s applied when temperatures are low, so you get the maximum value since heat breaks it down more quickly.

Watch soil profiles and plan to plan

“Coming off a season like we had last year, we need soil profiles to be as full as possible,” he says. “If you can control all the mustards and henbit, you’ve got a better start out of the gate next spring.”

El Niño is another reason winter weed control is critical this year. With extra winter moisture comes increased weed pressure. If allowed to grow unabated, weeds will suck up more moisture and nutrients. And, if it gets too wet, tillage equipment can’t be used for fear of soil compaction.

Another weed control tool Joiner notes is Quelex® Herbicide from Corteva. “Quelex is effective at managing weeds in winter wheat and is a good selection going into early spring. It’s also effective at helping manage weeds in corn. It’s generally applied in the spring, but plan for it now.”

Seed treatments are also important to consider.

“If I was a grower and getting ready to plant wheat, oats or triticale, I’d take a hard look at Lumivia® Insecticide Seed Treatment because armyworms are a big pest early on in this region in the fall. Young oat, wheat and triticale plants don’t tolerate a lot of feeding from armyworms. Lumivia can help get a crop off to a good start. It’s a lot easier to apply this seed treatment to seeds, run them through a drill and plant them than to go back and repeatedly spray a crop to try and control early season armyworms,” Joiner says.”

He’s adamant about planning well, citing Abraham Lincoln, “If you give me six hours to chop down a tree, I’ll spend the first four hours sharpening the axe.”

Whether you’re growing corn, soybeans, wheat, sunflowers or anything else, Joiner says to spend those important “four hours” with a professional you know and map out a game plan that makes sense.

“Use tools such as TruChoice, a great program that ties seed and crop protection choices with Corteva and Pioneer products,” he says. “Talk through some strategies and do not think about doing the same thing over and over.

“If your weed control program is working, maybe it’s time to break it. Perhaps you take a product like LeadOff or Quelex and work them in or consider a strategy that includes Resicore® Herbicide on corn in early spring. Simply consider approaches you’ve not tried before. This planning can ensure you’re not leaving money on the table.”

“You’re essentially laying down a piece of black plastic to keep your fields clean.”

El Niño is another reason winter weed control is critical this year. With extra winter moisture comes increased weed pressure.

New Corteva/Pioneer products

Years of research, trials support new products

It can take years of research and in-field testing before new products reach the market. Eric Scherder, U.S. Crop Protection Launch Leader for Corteva and his team come in 18 to 24 months before an anticipated product launch to ensure internal, regulatory personnel, retailers and customers understand what the new product is and how it can deliver value to their operation. It’s no small job.

It can take years of research and in-field testing before new products reach the market. Eric Scherder, U.S. Crop Protection Launch Leader for Corteva and his team come in 18 to 24 months before an anticipated product launch to ensure internal, regulatory personnel, retailers and customers understand what the new product is and how it can deliver value to their operation. It’s no small job.

“We have a deep and broad portfolio that includes a lot of products that meet a lot of needs,” Scherder says. “In the last three years alone, we’ve launched over 30 new crop protection products. For example, we recently launched Salibro™ nematicide for vegetable crops and perennial tree and fruit crops. In his opinion, Salibro is the first true opportunity to bring a non-fumigant solution to the marketplace that is a real game-changer for customers.”

He adds, in the last three years, Corteva has launched eight new combinations of seed-applied technologies. Plus, the recent introductions of weed control innovations like Rezuvant® herbicide, Kyro™ herbicide, HighNoon® herbicide and the Enlist® weed control system highlight Corteva Agriscience’s new products.

“Growers are looking for herbicides that deliver flexibility and wider application windows, and we’ve been fortunate to bring new solutions to various markets,” Scherder says. “And, whether it’s the canola, corn or soybean markets, there are certain diseases we face yearly that growers are looking for solutions. That’s one reason we launched Viatude™ fungicide to fight white mold.”

The biological segment of the agriculture market continues to grow rapidly. It has allowed our research and development teams the ability to deliver new ways to solve specific agronomic problems that farmers face each day. For example, Utrisha® N helps plants fix nitrogen from the atmosphere, and Utrisha P® helps plants absorb and take up phosphorous from the soil.

“We’re trying to mitigate stress that affects yields such as weeds, diseases, insects and overall plant stress. For example, we’re now able to use these biologicals in conjunction with other traditional products to round out a portfolio for growers to bring as much stability as possible to their farming operation to optimize yield,” Scherder says.

Corteva also is working to ensure biological products are as stable as possible.

“One thing growers must understand is that when they buy a fungicide, herbicide, insecticide or similar product, these products are generally stable over a wide range of storage temperatures or application environments. In many cases with biologicals, we’re dealing with living organisms. How we store, handle and apply these products can have a huge impact on their overall performance of some biological products. Understanding how to properly apply and store any product is important, but it is of upmost importance when dealing with agricultural biological solutions.

Proven research practices are critical

“When you use biologicals, sound research and development process are critical to characterize these products. This is why we use sound science. We look at the entire development and launch process, from the characterization and development of a new biological through storage and handling aspects and application considerations, so that we can deliver biologicals that have the same quality a grower has come to expect from our synthetic pesticides. Plus, Corteva has offered biologicals for 20 years, so we have experience producing efficacious products.”

Scherder emphasizes the importantance of understanding how you’re going to use a biological product and what you’re going to mix with it in the tank. Making sure the pH of the water isn’t too high and it’s not too highly chlorinated, generally above two parts per million to ensure viability of the biological organisms in the tank are aspects you may have to consider.

It is equally important to understand what a biological brings to your operation. For example, if you fertilized for optimum yield and used Utrisha N in a drought year where yields were 30 to 40 bushels off, there’ll be an excess of nitrogen in the field. If your only measurement of a new product’s effectiveness is yield, you can’t always truly evaluate the product’s performance and why multiple years of evaluation are important.

“This is why working with your local retailer and conducting on-farm trials across multiple fields and strips are good practices to see how a biological will work on your operation,” Scherder says. “Wanting increased yield is natural, but if there are limiting factors in your operation you are not addressing, spending money on something that is not yield limiting won’t increase yield, it doesn’t mean the product didn’t work that year, it was just not a limiting factor that year.

“If I’m going to maximize ROI, there are certain things I don’t cut out of my programs from one year to the next. For me, nitrogen stabilizers or a product like Utrisha-N and pre-emergence herbicides for a crop, regardless of the season, are an absolute. In-season fungicides also paid a lot of dividends throughout the Midwest over multiple years, even in a dry year like 2023. That is another factor I would look to keep in my operation.”

“Growers are looking for herbicides that deliver flexibility and wider application windows, and we’ve been fortunate to bring solutions to these markets.”

It is equally important to understand what a biological brings to your operation.

Equipment advances

Equipment advancement continues at a rapid clip

Step into the cab of a combine, tractor or sprayer today and it’s almost like stepping into a spaceship with all the different technologies present. There will be more in next year’s models.

“The industry is moving at the fastest rate of change since we transitioned from horse- and mule-drawn equipment to tractors powered by internal combustion engines,” Austin Gellings, Director of Agriculture for the Association of Equipment Manufacturers, says. “New technologies are ideally making farmers’ jobs easier and helping them be more efficient and precise. We’re trying to help them meet the challenge of producing more with less while maintaining sustainability,

“The industry is moving at the fastest rate of change since we transitioned from horse- and mule-drawn equipment to tractors powered by internal combustion engines,” Austin Gellings, Director of Agriculture for the Association of Equipment Manufacturers, says. “New technologies are ideally making farmers’ jobs easier and helping them be more efficient and precise. We’re trying to help them meet the challenge of producing more with less while maintaining sustainability,

“All of this new equipment and technology may make farming easier, but it also creates more information for farmers to manage. The industry’s job is to ensure that when farmers operate a piece of machinery, they know how to fully use and optimize all the data generated by it.”

Gellings stresses that none of even the most advanced innovations being released is a silver bullet. Rather, it is one more tool in the proverbial toolbox. It’s also important to remember every farm is different and every farmer will use data differently.

Supports sustainability efforts

Horsepower aside, equipment will continue to provide farmers increasing efficiency, precision and dependability. Fewer passes, greater fuel economy, and greater seed placement, depth and accuracy are customers’ normal expectations. Fertilizer, herbicide, insecticide, foliar nutrients and other applications have never been more targeted than they are now. Auto guidance systems will continue to reduce overlap.

“These are great attributes and they’ll keep improving,” Gellings says. “They’re great for the environment and, as importantly, go straight to farmers’ bottom lines. Part of sustainability is the economics of it.

“Plus, sustainability practices can extend the life of equipment. With fewer passes across the fields, we can save more fuel and save wear and tear on equipment.”

The fully autonomous operation is coming. As for what isn’t already here, don’t expect it to arrive all at once.

“The industry has been in some stage of autonomy for several years. Autosteer and a few other technologies have been proven, but the time is coming when we’ll have remote operations with farmers not having to be in the fields. In addition to equipment now being tested in row crops, a lot of existing and start-up manufacturers are delivering innovative technologies that are accurate, safe and help remove farmworkers from dangerous working conditions,” Gelling says.

“In addition to fully autonomous machines, some companies offer technologies to bolt onto existing equipment and make a machine operate autonomously. We’re seeing an amazing number of options. This makes scalability more likely for these companies and gives farmers multiple autonomous options to consider.”

Autonomy and precision agriculture are two key issues farmers consider and the top ones the industry is working to address. There are realistic hurdles to adoption, most notably the need for better rural broadband service. For farmers to transfer data from equipment to the cloud requires connectivity at the farm. It’s also important that farmers, agronomists and everyone in the value chain understand how to manage the large amount of data gathered.

“We’re working with farmers now so they can better understand the value of this data and how it can be used to make their farms more efficient. The technology can only get us so far, but the data provides insights to help make better decisions about genetics, fertilizers and crop protection products. That data can even go toward improving the equipment and making it more accurate,” Gellings says.

This data, along with newer equipment, seed technologies and crop input products will also help reduce use of the all-important input: water.

It will also likely create closer relationships between dealers and customers. Gellings says much of the responsibility of helping farmers implement these new technologies lies with dealer personnel. As is normal, farmers will want and need training to be comfortable buying the equipment. In addition to selling, delivering and servicing equipment, dealers and customers will work together to maximize equipment operation. Some dealers are already into data usage management, so the technology adoption process is well underway.

More precision, more efficiency, reduced crop inputs, reduced water use. Increased sustainability. What’s not to like about what’s coming?

“The industry is moving at the fastest rate of change since we transitioned from horse- and mule-drawn equipment to tractors powered by internal combustion engines.”

It will also likely create closer relationships between dealers and customers.

Drones

Helping customers’ crops soar

Since their commercialization, drones have proven those who work in agriculture are tech friendly. Those who work at Corteva and Pioneer are further proof.

Danny Brummel is the Agronomic Resource Manager for Corteva. He serves as the Pioneer Agronomy Science Support Contact for the far western U.S., coordinates on-farm research trials for Pioneer and leads Pioneer’s commercial drone program. The latter includes training agronomists and sales representatives to be pilots, coaching on how Pioneer personnel can use the technology to help customers and making certain programs remain in regulatory compliance.

Danny Brummel is the Agronomic Resource Manager for Corteva. He serves as the Pioneer Agronomy Science Support Contact for the far western U.S., coordinates on-farm research trials for Pioneer and leads Pioneer’s commercial drone program. The latter includes training agronomists and sales representatives to be pilots, coaching on how Pioneer personnel can use the technology to help customers and making certain programs remain in regulatory compliance.

Brummel says drones began being used immediately after their commercialization around 2010.

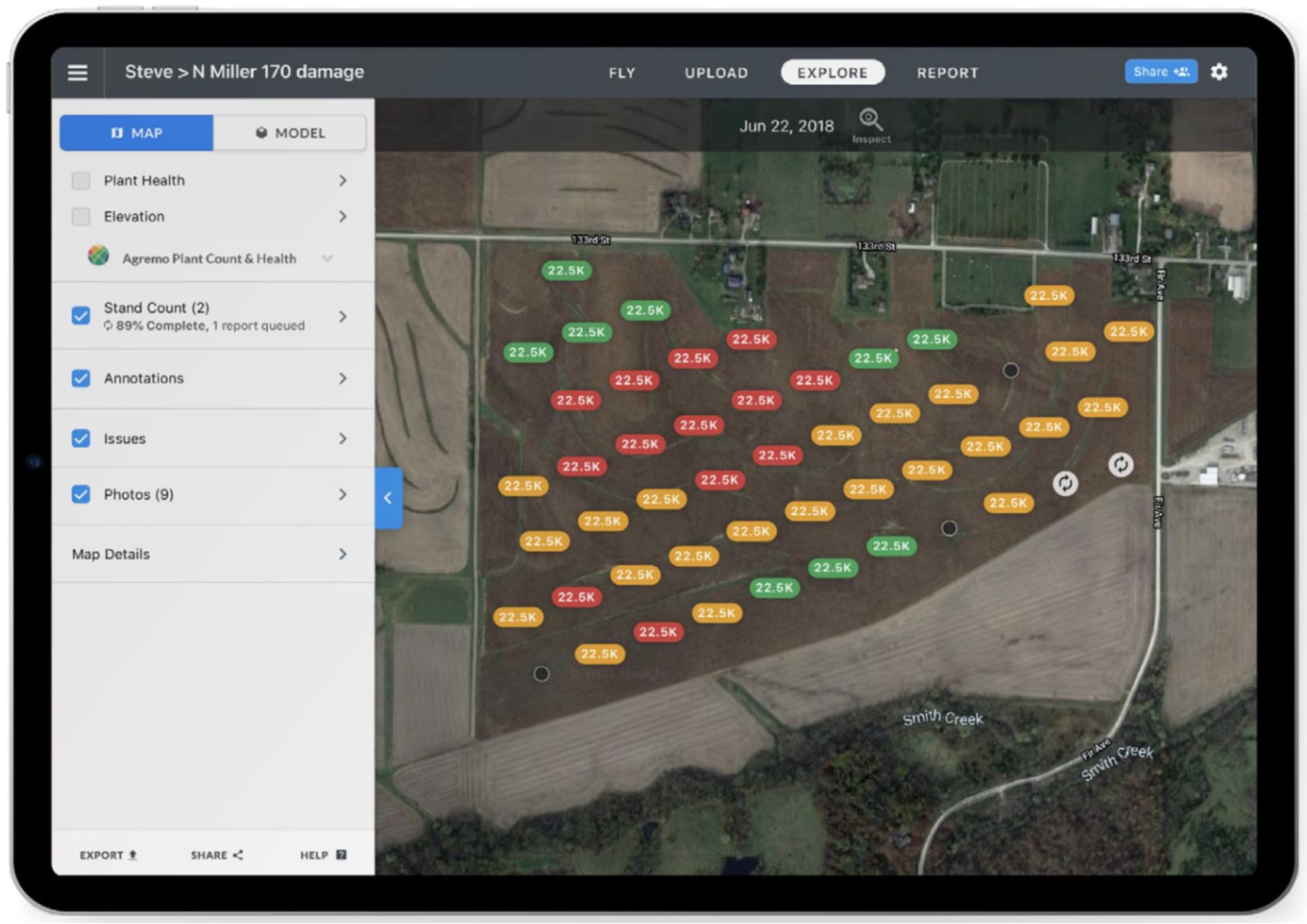

“We use imaging drones throughout the growing season to help our customers,” he says. “Early in the season, we help them collect stem counts to assess the standing plant population. Should there be an issue in a field, we can use this information to help them with replanting decisions. Throughout the rest of the season, we capture plant health imagery to identify areas of a field that are doing well, and areas that are stressed with disease pressure, insect damage or

“Before drones, we’d discover these spots at harvest or on the yield monitor. Today, we can identify what’s going on and take any corrective action that needs to be done.”

Early in this past growing season, a Pioneer agronomist flew a stand assessment for a customer. They saw one area of the field had a much lower plant population than expected.

“When the agronomist met with the customer, it turned out to be a planting error,” Brummel says. “Luckily, it was caught early enough that they could replant that part of the field and ensure they were on target with their plant population. It would have been harvest time when they discovered this were it not for the drone assessment.”

For dairy customers, Pioneer personnel can fly drones over silage bunkers and calculate the volume and amount of silage available to feed cattle. The drones can be used throughout the year so dairy producers can see how much feed they’ve used and how much is left over.

Drones are helpful after wind events, too. If a tornado, derecho or other severe wind event hits an area, drones can be used to assess crop damage and help growers quickly figure out which parts of fields have what type of damage in a fraction of the time it would take walking the fields.

“What used to take you hours or even days to get accurate stand counts across a large field in the past takes about 15 minutes when we fly a field and capture the field assessment,” Brummel says. “We can do the same with plant health, well.

“After the drone lands, you’ll have the imagery on your iPad or phone. Then, you can walk to the spot and investigate. It really goes straight to the bottom line when you think about how much time drones save you. Plus, we can find out so much more than we could before. We can’t look at every single plant, but a drone can.”

Finding out more is part of what new product research is about. Brummel says drones are used in research to help develop new products. Drones allow researchers to capture more data to use. The data gathered today is more consistent and there’s a lot more of it than there used to be, giving researchers more information to hone new product qualities.

Customers who own their own drones aren’t left in the cold.

“Our work complements what farmers use their drones for,” Brummel says. “It’s exciting when someone buys their first drone. Sometimes they’re not exactly sure what to use the drone for when they first get it. We’ll advise them on what software they can use and how to assess crops or crop damage. We can even work together. In some cases, customers can’t fly all of their fields, so we come in and help.”

More than just images

Brummel says more growers are starting to use spray drones to apply crop protection products. Take a fungicide application for example. Compared to using a high-clearance sprayer or manned airplane, a drone can apply product around a task line very quickly and accurately. Plus, with the limited number of pilots for manned aircraft, getting the fungicide applied at the right time could be a challenge. Agronomically, growers using drones are improving their situations, according to Brummel.

“Another use of drones becoming more common is to seed cover crops while another crop is still standing,” Brummel says. “This is more efficient than making planter passes across fields. Plus, the cover crops work well with environmental soil nutrient preservation, erosion prevention and sustainability goals.

Drones are improving

The drone industry is advancing quickly. Brummel says it’s similar to the cellphone industry where new models come out every year, and within five years, existing drones are essentially obsolete.

“Sensors are greatly improving, as are RGB cameras, which are somewhat like the cameras in our cellphones,” Brummel says. “The resolution is now good enough that we can separate plants and count the plant population. In addition to seeing that an area is stressed, we may be able to identify the specific disease or insect causing the problem without going into the field. The efficiency gains will be amazing.”

Battery life is quickly getting better. Five years ago, it was 20 minutes. Last year, it was 30 minutes. New drones now have about 40 minutes. This further reduces limitations.

“Corteva is highly invested in drone technology and the drone segment, in general,” Brummel says. “We want to help customers, as well as our research teams, so they can develop better seed products. We have the largest agricultural drone fleet in the world, including thousands of sales representatives, scientists and agronomists piloting drones around the globe.

“This is especially important from a research perspective. Humans can only be so consistent when scoring traits or diseases. We can now fly drones and get a numeric value for how green or how susceptible plants are.”

In addition, Corteva has internal research teams with specific roles to develop new models for drones to help customers.

“We know what challenges our customers face, so we’re directing our research resources to help address those challenges,” Brummel says.

“What used to take you hours or even days to get accurate stand counts across a large field in the past takes about 15 minutes when we fly a field and capture the field assessment.”

Corteva has the largest agricultural drone fleet in the world.

Risk management

Manage risk with confidence

One guarantee about 2024 is that it will come with risks of all kinds. It will also come with effective tools to help manage them.

One offers analytical tools to help farmers handle risk and margins. The CME Group, often referred to as The Chicago Mercantile Exchange, is the largest agricultural exchange with 18 products for livestock, dairy, grains and oilseeds. The agricultural business line has been part of CME for 170 years and futures options were added about 39 years ago.

Steve Staysis is Senior Director working on the agricultural business line. He started his career on a trading floor trading corn and soybean options.

“Our role is to be a neutral party and not offer guidance or advice,” he says. “We act as the buyer to every seller and the seller to every buyer. Nor do we directly solicit business.

“However, we try to offer as much information and tools to help guide the risk management process to brokers or farmers. Over the years, we’ve built multiple analytical tools with our data to help farmers manage margins using our products.”

CME offers futures and options as its primary products. Options let users define risk in a specific way. Staysis says options almost act as insurance policies when the owner sets a specific price for a put option. Should prices increase unexpectedly, farmers are able to participate in the upside movement while still being protected in an adverse downward price swing.

Futures let users lock in profit margins and sleep soundly knowing price is locked in.

He adds that CME does not deal directly with farmers who should engage brokers or commodity merchants to establish risk management and grain marketing programs.

Markets evolving

In addition to becoming electronic, the market now serves customers around the world. Corn and soybeans are benchmarks and trade volumes have increased over the years. In fact, 2023 is a record trading year.

“This growth in participation gives people more transparency and access to the ag markets,” Staysis says. “It is beneficial for participants to see exactly where prices for corn, soybeans and wheat are, so they can manage risk and hedge throughout most of the day. We close at 1:20 p.m. Central time and reopen at 7:00 p.m. Central.

“With all the risks in the world such as geopolitical concerns and weather events, it’s important for people to have access to their trades to mitigate these risks.”

He’s right. Drought drove a lot of the increased volume CME had this year. The threat of drought did, too.

“There’s a lot of uncertainty in the market related to weather,” Staysis says. “Naturally, with ag products, the seasonality will create price movements throughout the year. It’s the result of market participants mitigating their risk during specific periods of the year.

“Being a producer isn’t easy. There are a lot of unknowns and a lot of costs, especially as the industry changes. Input costs are increasing. Machinery is expensive. There is a lot of cash outlay. We are here to mitigate risk to offset some of these realities so producers can lock in margins. It helps them to operate comfortably as they lay out cash for seed and inputs. With futures and margins, producers can control more of their marketing and stabilize their operations.”

Work with brokers

Staysis readily advises engaging a broker or risk management consultant for managing futures and options. Many have been in business for a long time and understand the nuances of the CME products, and some are farmers, as well.

“Each person will have different risk tolerances and a good broker will help find a combination of marketing strategies that fit the client,” he adds.

Ultimately, a broker or consultant will find the right mix of CME tools to ensure farmers’ marketing goals are met year after year.

“With all the risks in the world such as geopolitical concerns and weather events, it’s important for people to have access to their trades to mitigate these risks.”

“A good broker will help find a combination of marketing strategies that fit the client.”

From weather to weeds and all things in between, there’s still time to get ready for 2024. Engage with trusted advisors, monitor short- and long-range forecasts from The Climate Prediction Center and local weather sources and try new hybrids or varieties to determine how they can meet your production goals.

We’ll check back with these and other experts to examine additional opportunities once the 2024 growing season is underway.